CONTENT

CAMPAIGN SPECIAL PRICE 2025

ปั๊มลมสกรู Fixed Speed Refurbish ราคาพิเศษ แคมเปญพิเศษ เครื่องอัดอากาศ Atlas Copco รุ่น G series ใช้งานได้ต่อเนื่อง 24 ชั่วโมง พร้อมการรับประกันจากโรงงาน สภาพเครื่อง 100% รุ่น 2kW (3HP), 11kW (15HP) และ 75kW (100HP)

เครื่องอัดอากาศสำหรับบรรจุภัณฑ์อุตสาหกรรมอาหาร

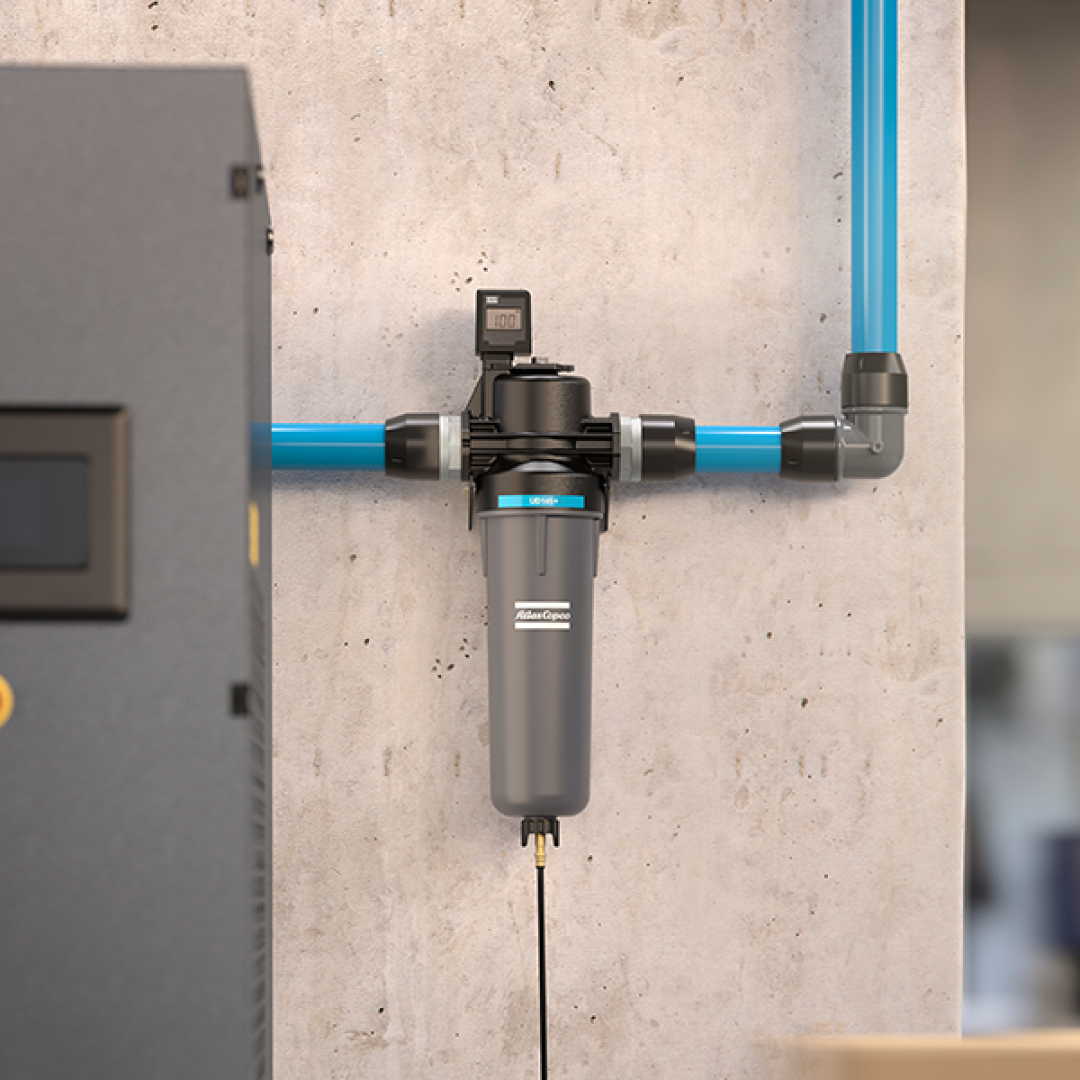

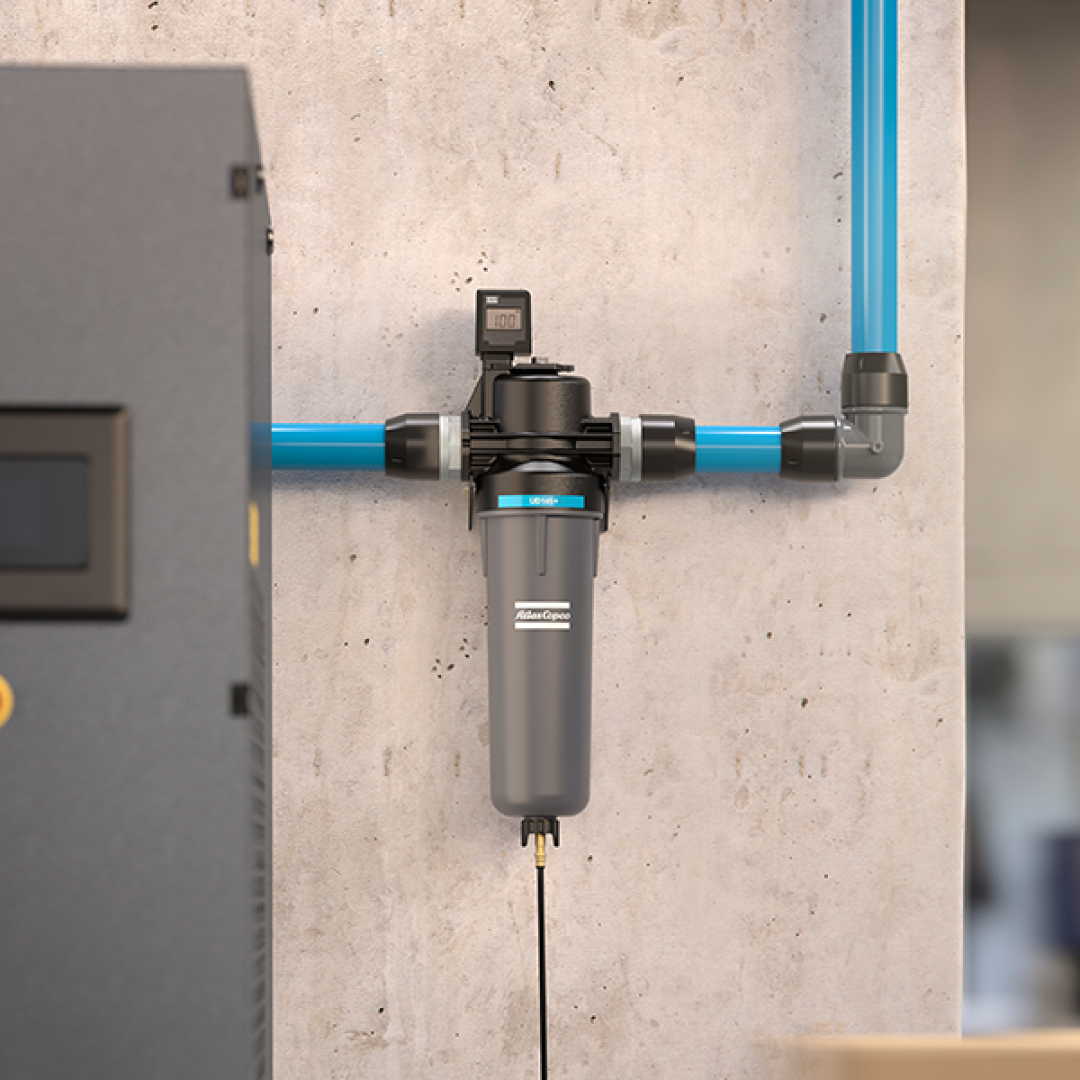

ระบบลมอากาศกับการบรรจุภัณฑ์ Packaging ในอุตสาหกรรมอาหารนั้นมีความเกี่ยวข้องกันมาอย่างยาวนาน ลมอัดถูกใช้ในหลายขั้นตอนของกระบวนการบรรจุหีบห่อของอาหาร หรือแม้กระทั่ง Packaging ของเครื่องสำอาง และส่วนที่ถูกใช้งานอย่างหนักหน่วงคือการขับเคลื่อนเครื่องจักรที่ใช้ในการลำเลียง ไปจนถึงการบรรจุผลิตภัณฑ์ลงกล่องหรือลงหีบห่อ เครื่องจักรเหล่านี้ทำงานตามช่วงเวลาและบางทีก็แทบไม่ได้หยุดพักเนื่องจากต้องใช้เวลาในการตั้งค่าเครื่องจักรอีกครั้ง และในกระบวนการลำเลียงที่พบว่าลมอัดถูกใช้แทบทุกโรงงานนั้น ลมอัดที่ส่งมอบอย่างต่อเนื่องมีส่วนช่วยให้กระบวนการผลิตเป็นไปตามเวลาที่ตั้งไว้

ทำไมเทคโนโลยี VSD จึงประหยัดพลังงานมากกว่าเมื่อเทียบกับ Fixed Speed?

ผู้ใช้งานระบบลมอัดหลายท่านคงจะคุ้นเคยกันดีกับคำว่า Variable Speed Drive หรือบางครั้งเรามักเรียกสั้นๆ ว่า VSD แต่หลายท่านเองอาจจะยังไม่ทราบว่า VSD คืออะไร? แล้วคุณล่ะ ทราบไหมว่า VSD คืออะไร? วันนี้เราจะพามาทำความรู้จักกับเทคโนโลยี VSD กันค่ะ!

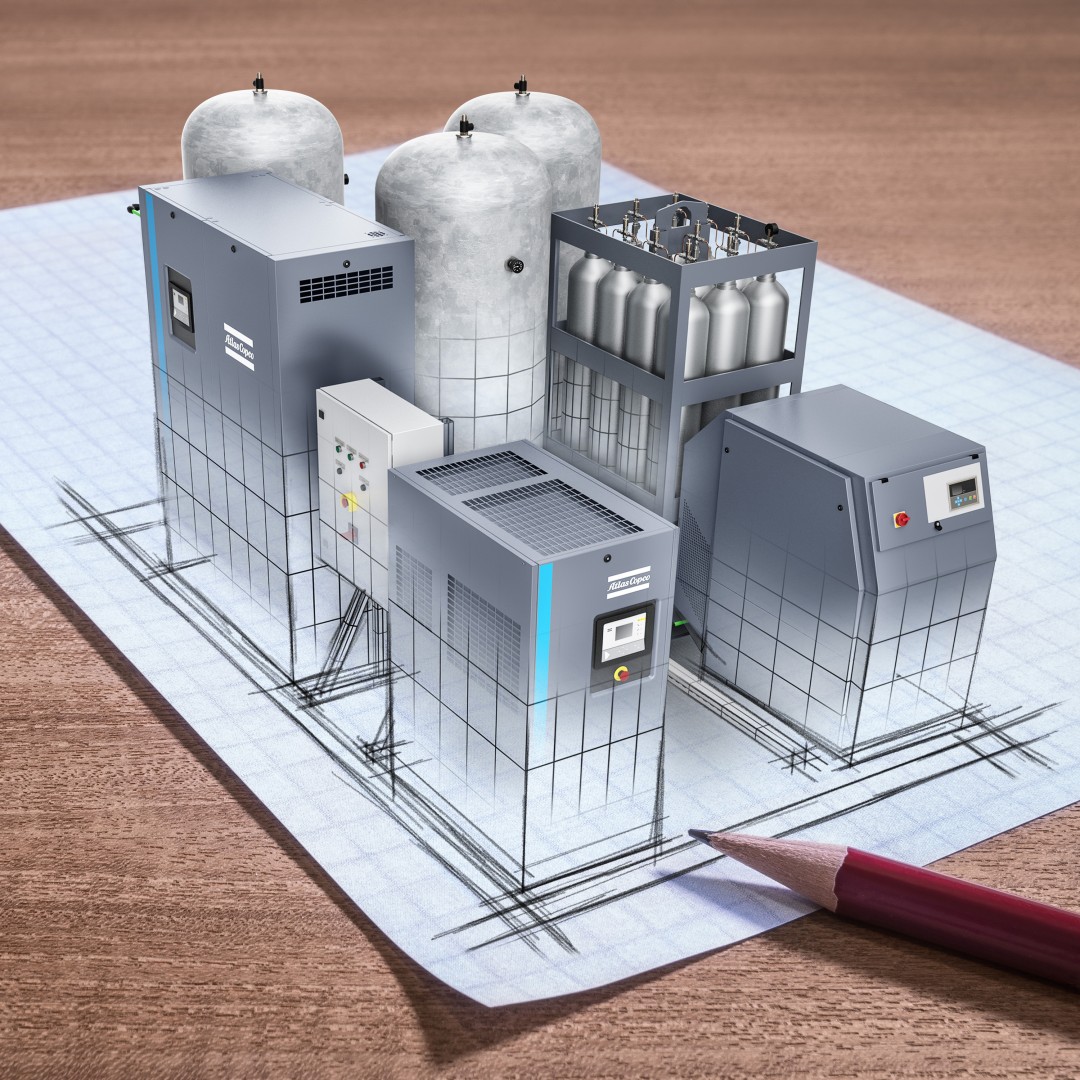

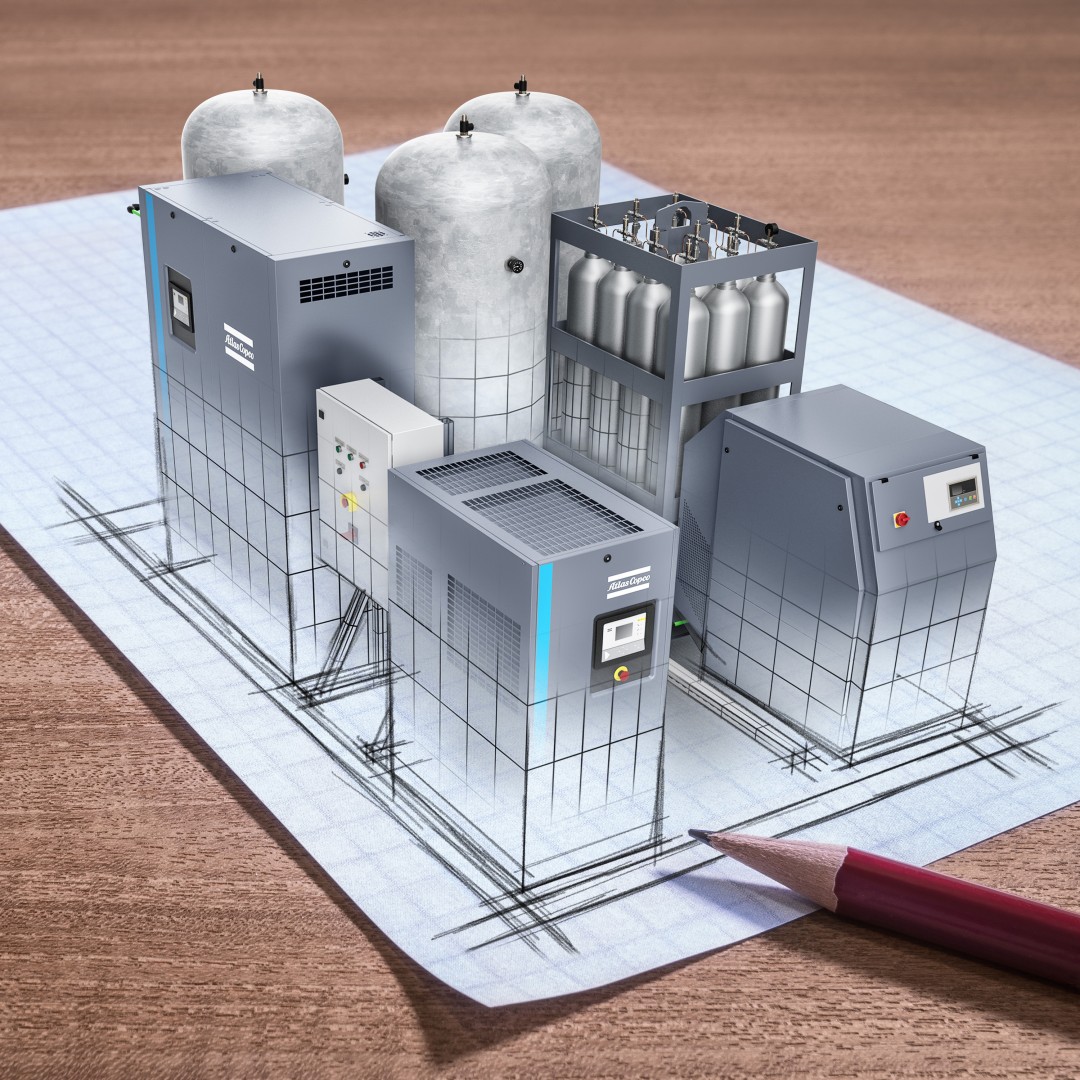

คู่มือการผลิตแบตเตอรี่ EV

ในคู่มือนี้คุณจะได้เรียนรู้ทุกสิ่งที่จำเป็นเกี่ยวกับโซลูชั่นอากาศอัดและก๊าซสำหรับการผลิตแบตเตอรี่รถยนต์ไฟฟ้า (EV) แอตลาส คอปโก้ มีโซลูชั่นอากาศอัดและก๊าซที่ครอบคลุมสำหรับแบตเตอรี่ลิเธียมไอออนสำหรับโรงงานผลิตรถยนต์ไฟฟ้า

Smart Control or Equalizer 4.0

มีการนำปั๊มลมในโรงงาน Optimized เชื่อมต่อกัน ทำงานไม่แยกจากกัน ผลที่ได้รับคือ พลังงานสูญเสียเปล่าประโยชน์, Unload Energy และ Pressure Band ต่ำมาก นั้นหมายถึงค่าพลังงานไฟฟ้าที่ต้องจ่ายจากเดิมลดลงทันที รวมถึงค่าใช้จ่ายในการต้องเปลี่ยนอะไหล่ทุกวาระของปั๊มลม แต่ละเครื่องคุ้มค่าสูงสุดของการใช้งาน

Data Logger or iitrack

ช่วยให้โรงงานทราบถึงพฤติกรรมการใช้ลมอัดในแต่ละช่วงเวลาของไลน์ผลิต และส่วนเกินของค่ากระแสไฟฟ้าที่สูญเสียไปโดยเปล่าประโยชน์ของปั๊มลม เพื่อนำข้อมูลที่ได้มาปรับปรุง หรือแก้ไขเพื่อลดรายจ่ายพลังงานไฟฟ้าของปั๊มลมในโรงงานอย่างมีประสิทธิภาพ รวมถึงการลด Carbon Footprint ซึ่งจะมีผลบังคับใช้ในอุตสาหกรรมในอนาคตอันใกล้นี้